PA66美国杜邦10B40HS1 40%矿物增强热稳定耐热尼龙66聚酰胺工程塑料

-

PA66美国杜邦10B40HS1 40%矿物增强热稳定耐热尼龙66聚酰胺工程塑料

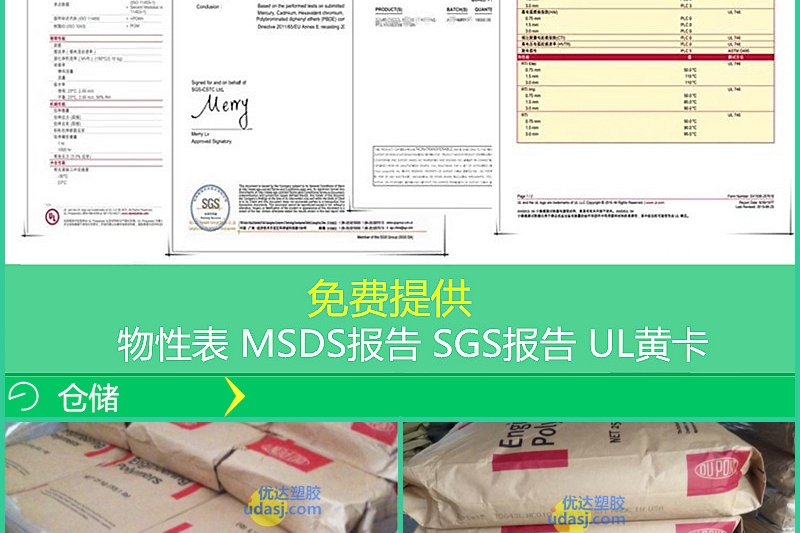

DuPont Performance Polymers Minlon® 10B40HS1 BK061 Nylon 66 (Unverified Data) 物性表

物理性能

额定值 (公制)

额定值 (英制)

测试方法

比重

1.51 g/cc

1.51 g/cc

DAM; ASTM D792

密度

1.51 g/cc

0.0546 lb/in³

DAM; ISO 1183

填料含量

40 %

40 %

DAM

线性成型收缩率

0.0040 cm/cm

@Thickness 1.60 mm

0.0040 in/in

@Thickness 0.0630 in

Flow; DAM

0.0040 cm/cm

@Thickness 3.20 mm

0.0040 in/in

@Thickness 0.126 in

Flow; DAM

0.0060 cm/cm

@Thickness 6.40 mm

0.0060 in/in

@Thickness 0.252 in

Flow; DAM

0.0090 cm/cm

@Thickness 1.60 mm

0.0090 in/in

@Thickness 0.0630 in

Transverse; DAM

0.0090 cm/cm

@Thickness 3.20 mm

0.0090 in/in

@Thickness 0.126 in

Transverse; DAM

0.011 cm/cm

@Thickness 6.40 mm

0.011 in/in

@Thickness 0.252 in

Transverse; DAM

线性成型收缩率,Flow

0.0040 cm/cm

@Thickness 2.00 mm

0.0040 in/in

@Thickness 0.0787 in

DAM; ISO 294-4

线性成型收缩率,横向

0.0090 cm/cm

@Thickness 2.00 mm

0.0090 in/in

@Thickness 0.0787 in

DAM; ISO 294-4

机械性能

额定值 (公制)

额定值 (英制)

测试方法

抗张强度(断裂)

95.0 MPa

@Temperature 23.0 °C

13800 psi

@Temperature 73.4 °F

DAM; ISO 527

抗张强度

87.0 MPa

@Temperature 23.0 °C

12600 psi

@Temperature 73.4 °F

DAM; ASTM D638

伸长率 (断裂)

2.5 %

@Temperature 23.0 °C

2.5 %

@Temperature 73.4 °F

DAM; ISO 527

2.5 %

@Temperature 23.0 °C

2.5 %

@Temperature 73.4 °F

DAM; ASTM D638

拉伸模量

10.0 GPa

@Temperature 23.0 °C

1450 ksi

@Temperature 73.4 °F

DAM; ISO 527

弯曲强度

148 MPa

@Temperature 23.0 °C

21500 psi

@Temperature 73.4 °F

DAM; ASTM D790

弯曲模量

8.62 GPa

@Temperature 23.0 °C

1250 ksi

@Temperature 73.4 °F

DAM; ASTM D790

9.50 GPa

@Temperature 23.0 °C

1380 ksi

@Temperature 73.4 °F

DAM; ISO 178

悬壁梁缺口冲击强度

0.320 J/cm

@Temperature 23.0 °C

0.599 ft-lb/in

@Temperature 73.4 °F

DAM; ASTM D256

悬壁梁无缺口冲击强度

3.20 J/cm

@Temperature 23.0 °C

5.99 ft-lb/in

@Temperature 73.4 °F

DAM; ASTM D4812

悬壁梁缺口冲击强度

2.50 kJ/m²

@Temperature -40.0 °C

1.19 ft-lb/in²

@Temperature -40.0 °F

DAM; ISO 180/1A

3.50 kJ/m²

@Temperature 23.0 °C

1.67 ft-lb/in²

@Temperature 73.4 °F

DAM; ISO 180/1A

简支梁缺口冲击强度

0.200 J/cm²

@Temperature -40.0 °C

0.952 ft-lb/in²

@Temperature -40.0 °F

DAM; ISO 179/1eA

0.300 J/cm²

@Temperature 23.0 °C

1.43 ft-lb/in²

@Temperature 73.4 °F

DAM; ISO 179/1eA

热性能

额定值 (公制)

额定值 (英制)

测试方法

线形热膨胀系数 - 流动

500 µm/m-°C

@Temperature -40.0 - 23.0 °C

278 µin/in-°F

@Temperature -40.0 - 73.4 °F

DAM; ASTM E 831

500 µm/m-°C

@Temperature 23.0 - 55.0 °C

278 µin/in-°F

@Temperature 73.4 - 131 °F

DAM; ASTM E 831

500 µm/m-°C

@Temperature 55.0 - 160 °C

278 µin/in-°F

@Temperature 131 - 320 °F

DAM; ASTM E 831

500 µm/m-°C

@Temperature -40.0 - 23.0 °C

278 µin/in-°F

@Temperature -40.0 - 73.4 °F

DAM; ISO 11359-1/-2

500 µm/m-°C

@Temperature 23.0 - 55.0 °C

278 µin/in-°F

@Temperature 73.4 - 131 °F

DAM; ISO 11359-1/-2

500 µm/m-°C

@Temperature 55.0 - 160 °C

278 µin/in-°F

@Temperature 131 - 320 °F

DAM; ISO 11359-1/-2

线性热膨胀系数,横向流动

53.0 µm/m-°C

@Temperature -40.0 - 23.0 °C

29.4 µin/in-°F

@Temperature -40.0 - 73.4 °F

DAM; ISO 11359-1/-2

53.0 µm/m-°C

@Temperature -40.0 - 23.0 °C

29.4 µin/in-°F

@Temperature -40.0 - 73.4 °F

DAM; ASTM E 831

66.0 µm/m-°C

@Temperature 23.0 - 55.0 °C

36.7 µin/in-°F

@Temperature 73.4 - 131 °F

DAM; ISO 11359-1/-2

66.0 µm/m-°C

@Temperature 23.0 - 55.0 °C

36.7 µin/in-°F

@Temperature 73.4 - 131 °F

DAM; ASTM E 831

110 µm/m-°C

@Temperature 55.0 - 160 °C

61.1 µin/in-°F

@Temperature 131 - 320 °F

DAM; ISO 11359-1/-2

110 µm/m-°C

@Temperature 55.0 - 160 °C

61.1 µin/in-°F

@Temperature 131 - 320 °F

DAM; ASTM E 831

熔融温度

263 °C

505 °F

10°C/min; DAM; ISO 11357-1/-3

263 °C

505 °F

DAM; ASTM D3418

载荷下热变形温度(1.8 MPa)

205 °C

401 °F

DAM; ISO 75-1/-2

210 °C

410 °F

DAM; ASTM D648

可燃性(UL94)

HB

@Thickness 3.00 mm

HB

@Thickness 0.118 in

DAM; IEC 60695-11-10

HB

@Thickness 1.50 mm

HB

@Thickness 0.0591 in

DAM; IEC 60695-11-10

HB

@Thickness 0.710 mm

HB

@Thickness 0.0280 in

DAM; IEC 60695-11-10

加工性能

额定值 (公制)

额定值 (英制)

测试方法

加工(熔体)温度

295 °C

563 °F

DAM; Optimum

285 - 305 °C

545 - 581 °F

DAM

模具温度

70.0 - 120 °C

158 - 248 °F

DAM

100 °C

212 °F

DAM; optimum

干燥温度

80.0 °C

176 °F

DAM

干燥时间

2.00 - 4.00 hour

2.00 - 4.00 hour

DAM

水分含量

<= 0.20 %

<= 0.20 %

DAM

材料描述

测试方法

添加剂

Heat Stabilizer

DAM

外观

Black Color

DAM

Drying Recommended

Yes, if moisture content of resin exceeds recommended level

DAM

特性

Warpage, Low

DAM

Filler

Mineral filler

DAM

形式

Pellets

DAM

Generic

Nylon 66

DAM

Heat Stabilized

Yes

DAM

Material Status

Current

DAM

部件标识代码

>PA66-MD40<

ISO 11469; DAM

Polymer Family

Polyamide

DAM

Polymer Type

PA66

DAM

加工方法

Injection Molding

DAM

产品分类

Low Warp Resins

DAM

Mineral Reinforced Resins

DAM

树脂识别

PA66-MD40

ISO 1043; DAM

符合RoHS指令

Contact Manufacturer

DAM

Ultrasonic Weldable

Yes

DAM

用途

Appliance Components

DAM

Automotive Applications

DAM

Gears

DAM

Industrial Applications

DAM

Parts, Engineering

DAM

-