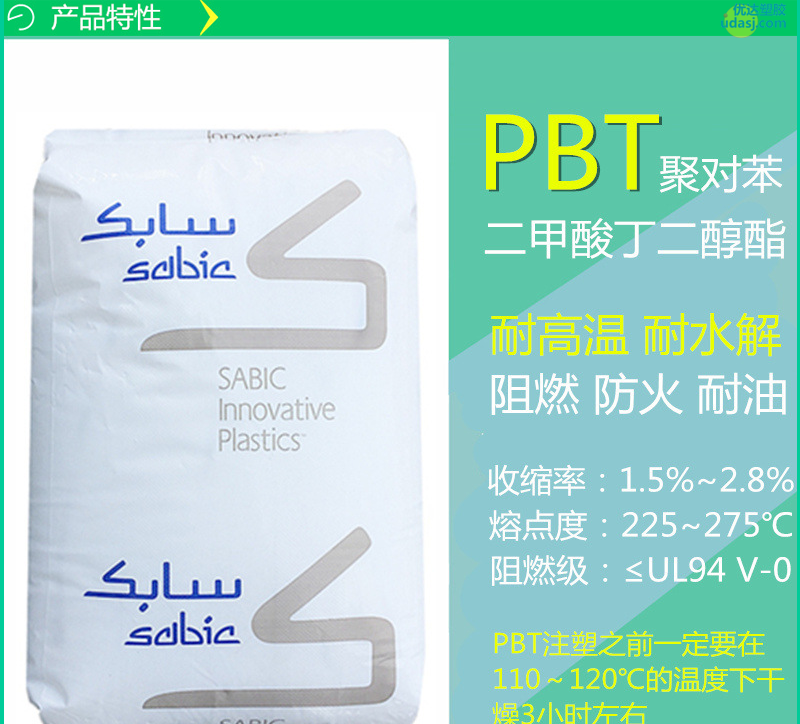

PBT 沙伯基础(原GE) 357M阻燃级 耐高温 耐候 抗紫外线 照明灯具 工程塑料

-

SABIC Innovative Plastics Valox® 357M PBT (Asia Pacific)

Polymer,Thermoplastic,Polyester, TP,Polybutylene Terephthalate (PBT)

SABIC Innovative Plastics (GE Plastics)

产品说明:

This data was supplied by SABIC-IP for the Asia Pacific region.

SABIC Innovative Plastics Valox® 357M PBT (Asia Pacific) 物性表 工程塑料

物理性能

额定值 (公制)

额定值 (英制)

测试方法

比重

1.34 g/cc

1.34 g/cc

ASTM D 792

吸水率

0.080 %

@Time 86400 sec

0.080 %

@Time 24.0 hour

ASTM D 570

线性模具收缩,Flow

0.0080 - 0.011 cm/cm

@Thickness 0.750 - 2.30 mm

0.0080 - 0.011 in/in

@Thickness 0.0295 - 0.0906 in

SABIC Method

0.010 - 0.014 cm/cm

@Thickness 2.30 - 4.60 mm

0.010 - 0.014 in/in

@Thickness 0.0906 - 0.181 in

SABIC Method

线性成型收缩率,横向

0.0090 - 0.013 cm/cm

@Thickness 0.750 - 2.30 mm

0.0090 - 0.013 in/in

@Thickness 0.0295 - 0.0906 in

SABIC Method

机械性能

额定值 (公制)

额定值 (英制)

测试方法

洛氏硬度(R 级)

117

117

ASTM D 785

抗张强度(断裂)

48.0 MPa

6960 psi

Type I, 50 mm/min; ASTM D 638

抗张强度(屈服)

48.0 MPa

6960 psi

Type I, 50 mm/min; ASTM D 638

伸长率 (断裂)

110 %

110 %

Type I, 50 mm/min; ASTM D 638

弯曲强度

82.0 MPa

11900 psi

1.3 mm/min, 50 mm span; ASTM D 790

82.0 MPa

11900 psi

1.3 mm/min, 50 mm span; ASTM D 790

弯曲模量

2.06 GPa

299 ksi

1.3 mm/min, 50 mm span; ASTM D 790

悬壁梁缺口冲击强度

5.30 J/cm

@Temperature 23.0 °C

9.93 ft-lb/in

@Temperature 73.4 °F

ASTM D 256

悬壁梁无缺口冲击强度

32.02 J/cm

@Temperature 23.0 °C

59.99 ft-lb/in

@Temperature 73.4 °F

ASTM D 4812

Gardner Impact

43.0 J

@Temperature 23.0 °C

31.7 ft-lb

@Temperature 73.4 °F

ASTM D 3029

43.0 J

@Temperature 23.0 °C

31.7 ft-lb

@Temperature 73.4 °F

ASTM D 3029

电气性能

额定值 (公制)

额定值 (英制)

测试方法

体积电阻率

>= 1.20e+16 ohm-cm

>= 1.20e+16 ohm-cm

ASTM D 257

介电常数

3.2

@Frequency 100 Hz

3.2

@Frequency 100 Hz

ASTM D 150

3.2

@Frequency 1.00e+6 Hz

3.2

@Frequency 1.00e+6 Hz

ASTM D 150

介电强度

18.5 kV/mm

@Thickness 3.20 mm

470 kV/in

@Thickness 0.126 in

in air; ASTM D 149

18.5 kV/mm

@Thickness 3.20 mm

470 kV/in

@Thickness 0.126 in

in oil; ASTM D 149

25.1 kV/mm

@Thickness 1.60 mm

638 kV/in

@Thickness 0.0630 in

in oil; ASTM D 149

耗散因数

0.0030

@Frequency 100 Hz

0.0030

@Frequency 100 Hz

ASTM D 150

0.030

@Frequency 1.00e+6 Hz

0.030

@Frequency 1.00e+6 Hz

ASTM D 150

耐电弧性

60 - 120 sec

60 - 120 sec

Tungsten, PLC code 6; ASTM D 495

相比耐漏电起痕指数(CTI)

250 - 400 V

250 - 400 V

PLC code 2; UL 746A

热丝引燃 (HWI)

30 - 60 sec

30 - 60 sec

PLC code 2; UL 746A

高电弧燃烧,HAI

15 - 30 arcs

15 - 30 arcs

surface, PLC code 3; UL 746A

高压电弧跟踪率,HVTR

80.0 - 150 mm/min

3.15 - 5.91 in/min

PLC code 3; UL 746A

热性能

额定值 (公制)

额定值 (英制)

测试方法

线形热膨胀系数 - 流动

91.8 µm/m-°C

@Temperature -40.0 - 40.0 °C

51.0 µin/in-°F

@Temperature -40.0 - 104 °F

ASTM E 831

124 µm/m-°C

@Temperature 60.0 - 138 °C

68.9 µin/in-°F

@Temperature 140 - 280 °F

ASTM E 831

载荷下热变形温度(0.46 MPa)

137 °C

@Thickness 6.40 mm

279 °F

@Thickness 0.252 in

unannealed; ASTM D 648

载荷下热变形温度(1.8 MPa)

98.0 °C

@Thickness 6.40 mm

208 °F

@Thickness 0.252 in

unannealed; ASTM D 648

UL RTI

120 °C

248 °F

UL 746B

UL RTI,机械冲击

120 °C

248 °F

UL 746B

UL RTI,机械无冲击

140 °C

284 °F

UL 746B

可燃性(UL94)

HB

@Thickness 0.450 mm

HB

@Thickness 0.0177 in

UL 94 by SABIC-IP

V-0

@Thickness 0.630 mm

V-0

@Thickness 0.0248 in

UL 94 by SABIC-IP

5VA

@Thickness 2.99 mm

5VA

@Thickness 0.118 in

UL 94 by SABIC-IP

材料描述

测试方法

UV-light, water exposure/immersion

F2

UL 746C

-